- VE testing takes much longer to perform, several hours as opposed to about one hour for roller testing.

- VE testing needs good conditions: Low wind days are needed, and obviously also daylight, which is more difficult in winter.

- For VE testing outdoors, the ground needs to be fairly robust, so that multiple runs don't degrade the ground and lead to a drift in the rolling resistance being measured. This generally means that for off-road applications, the ground needs to be dry. Again, that's difficult or impossible in winter (in the UK).

Monday 21 February 2022

Saturday 19 February 2022

Testing of tyre rolling resistance using rollers - Part 2, Setup improvements

Following on from Part 1 of the roller testing described in the previous post, I made a couple of important improvements:

Speed Sensor: In my Part 1 blog post, I explained that I didn't yet have the magnetic Garmin speed sensor that I'd ordered. I subsequently received the speed sensor through the post and installed it in a similar way to how Tom Anhalt did, setting the 'wheel circumference' on my Garmin head unit to 261mm, which is the measured roller diameter of 83.0mm, multiplied by pi.

I'm still a bit surprised the speed sensor works with the magnet triggering the sensor so quickly, at about 40-50 Hz (every 2-3 hundredths of a second!).

Front fork mount: Previously I had to prop myself upright using my elbow. I built a fork mount using a spare piece of chipboard flooring and a few spare bits of timber.

The axle itself is the axle clamp borrowed off my Thule 561 bike carrier (the 561 is now discontinued).

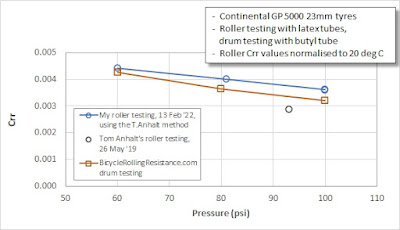

After making these two improvements, I wanted to check the effect on the rolling resistance measurements by re-doing the runs at 80 psi, using my road bike and Continental GP5000 tyre, as tested in Part 1. The results below (shown with blue triangle symbols) show that these two set-up improvements have quite a small effect on the results. It's quite reassuring that one week later, with some tweaks to the setup, I get very similar results to the previous weekend.

Sunday 13 February 2022

Testing of tyre rolling resistance using rollers - Part 1

A previous blog post from 2020 described my measurements of tyre rolling resistance that I did using the Virtual Elevation outdoor method.

- I used Tom's gravel tyre data recording and processing spreadsheet pretty much as-is. I saw little value in re-working the spreadsheet, or creating my own version. If I did so, I would only risk making mistakes. Only one change was needed, and that was the diameter of the rollers: Mine were 83mm in diameter whereas Tom's were larger, 114mm in diameter.

- I didn't have an old-fashioned Garmin magnetic speed sensor when I did this initial testing. I had already ordered one from a seller on eBay, but I was still waiting for it to be delivered. Instead I had to use my (newer) Garmin wheel hub based speed sensor, which I think works using an accelerometer to detect rotation frequency, in combination with a prescribed wheel circumference. This is a simplification, because keeping the wheel circumference fixed isn't quite right when the tyre pressure is changing. For this initial 'shakedown' testing, though, I think this simplification is fine.

- I didn't have a front fork mount. I later constructed one (to be described in a future Part 2 blog post), but for this initial test I had to improvise. Instead, I positioned the rollers next to a shelf (see photo below) and used my elbow to keep myself upright. This really wasn't as bad as it sounds! It's far from ideal though.

- For this testing, and for everything else, I used a Stages left-hand crank based power meter. Using a single-sided power meter is inferior to using a dual-sided power meter, but it's all I have unfortunately. At some point, I will invest in a dual-sided power meter.

Rear wheel weighing. I asked my wife to read off the number on the bathroom scales while I sat on the bike.

The results shown in the plot above are quite encouraging I think. Considering the small simplifications in my test (i.e. the lack of an appropriate speed sensor and lack of a front axle support), I think the results look reasonable. The trend and values are similar to the Bicycle Rolling Resistance data (orange points), although my CRR values should actually be lower than the BRR values, instead of higher, because my testing was done with a latex inner tube whereas BRR's testing is done with standard butyl tube.

Comparisons versus Tom Anhalt's data point (the black circle in the plot) should be a reasonable like-for-like comparison, with differences coming possibly only from the roller diameter, brand of rollers, and power meter differences. My CRR values are about 30% higher, which is quite a big difference. I can imagine a few possible explanations, but as this was the first time I've used my rollers, I wonder if the roller bearings need 'running in', which would reduce their friction losses and would therefore reduce the apparent CRR values. This is something that should become more clear if I do further testing.

On the positive side, my repeated point at 100 psi tyre pressure for the 4th run shows excellent repeatability with the equivalent point for the 1st run. The two data points at 100 psi are barely discernible on the plot because they are so close to each other.

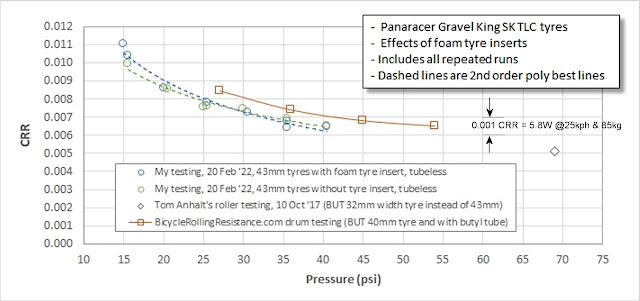

For my next set of testing, I will probably use my gravel bike and try to measure the effect of foam tyre inserts on the rolling resistance coefficient. This will be documented in a future blog post.